Rising To The Challenge

The evolving test requirements for Electric Vehicle battery packs means test specifications are constantly being pushed to new boundaries. JTS has risen to these challenges with our range of containerised test chambers. With extensive experience in the design and build of reliable high-performance bespoke environmental test chambers we provide solutions to large multi-national companies, both here in the UK and overseas.

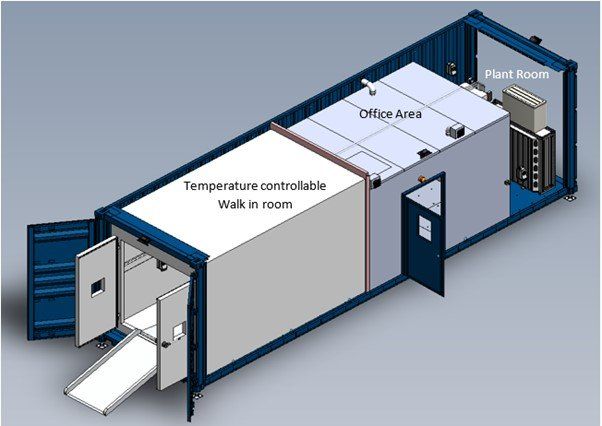

JTS has an ethos of working closely with customers and this proved invaluable with a recent design brief for a containerised test facility. The build specification required a temperature controlled test chamber, an office area for engineers and an area for refrigeration plant and the customer’s chiller.

Our design utilises a 30ft tunnel container with an additional personnel door for access to the office. A side window introduces natural light to the office and louvre panels facilitate a flow of fresh air through the plant area.

The 2m x 4m test area provides a controlled environment over a range of +20°C to +40°C, with capacity for test loads dissipating up to 10kw. The ceiling mounted air handling unit is fitted with a fan speed controller, allowing the customer to control the airflow within the chamber. A bunded anti-slip floor enables safe containment of any spilt test fluids, up to a depth of 100mm. Access for loading is via double doors at one end of the container and a fire rated personnel door gives access from the office. An array of IP65 rated 230V and 400v sockets are fitted either side of the test area for customer use.

For safety a 60 minute fire rated bulkhead is incorporated between the chamber and the 2m x 3.5m office area. Laminated insulation panels line this area and an aluminium anti-slip floor gives a clean bright working environment. Further enhancements include air conditioning, continual fresh air purge and emergency LED lighting.

The plant room at the end of the container houses a Bitzer Ecolite air cooled condensing unit and the cooling plant for the air conditioning system. Free space is also allocated in this area for the customer’s test load chiller and their Statx fire suppression system.

There will never be one design that fits all scenarios of testing. From containers to walk in rooms, floor standing to bench mounted, our wealth of experience and continuous product development enables JTS to engineer bespoke solutions.