Keeping you up to date...

By richard

•

October 17, 2025

We’re excited to welcome Alan Phillips to our service team. Alan joined us this summer and has already been making a big impact, helping customers get the very best out of their test chambers. 👏 At JTS, we know that regular servicing is the key to keeping your equipment reliable, accurate, and compliant. That’s why we offer a comprehensive Service Package designed to: ✅ Extend equipment lifespan ✅ Prevent costly breakdowns ✅ Maintain testing accuracy & compliance Our expert technicians provide: 🔧 Full functional checks 📏 Calibration & performance verification ⚙️ Replacement of worn parts 📝 Detailed service reports With JTS, you get fast, efficient service from specialists who know your chambers inside out — so you can keep operations running smoothly with minimal downtime. 📅 Ready to book your service? Drop us a message or get in touch today for your quotation andrea@jts-test-chambers.co.uk

By richard

•

September 19, 2025

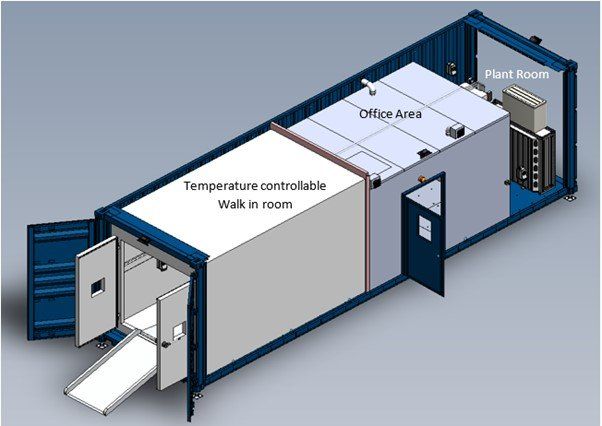

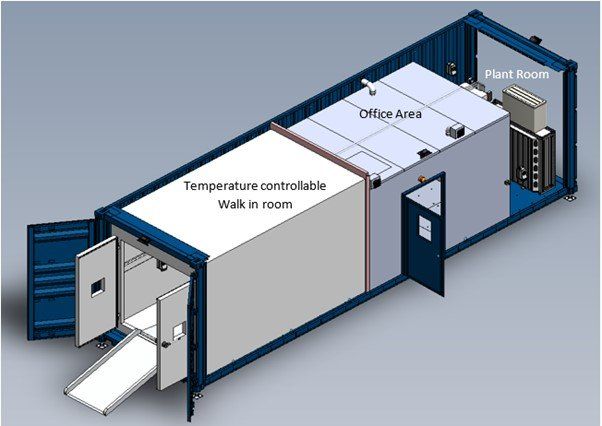

James Technical Services Limited having been involved in electric car, battery development and testing over the past 7 years have now installed two 11kW charging points at the factory in Talgarth mid Wales. These points can be used by customers and employees 😊 JTS have always been following the progress of the battery development and have purchased their first electric vehicle which will be used by the employees to carry out sales / site visits. The container test chamber below is used by various car manufacturers for electric vehicle battery testing. This is just one example of a battery testing facility JTS can supply.

October 15, 2024

JTS were asked by local councillor William Powell to help out refreshing a storage container used by Talgarth Town FC juniors and ladies. After some initial discussions and a quick cad mock up to agree the paint scheme the JTS team began to work on the project. This happened with the help of the Black Mountains College (Power) and Talgarth Building Supplies (Paint) and the JTS workforce. As you can see the container has had a new lease of life and we hope the guys using the container like the paint work! ‘Good news TTFC under 10’s celebrated a home victory with the team having a photo and the container used as a back drop!’

July 22, 2024

James Technical Services Limited having been involved in electric car, battery development and testing over the past 7 years have now installed two 11kW charging points at the factory in Talgarth mid Wales. These points can be used by customers and employees 😊 JTS have always been following the progress of the battery development and have purchased their first electric vehicle which will be used by the employees to carry out sales / site visits. The container test chamber below is used by various car manufacturers for electric vehicle battery testing. This is just one example of a battery testing facility JTS can supply.

By Gillian

•

February 1, 2023

An issue faced by many customers is how to achieve the most test capacity without impacting on chamber performance. Putting the maximum test load in and still achieving even distribution and stability is a challenge when building bespoke equipment. Airflow is key and having a good understanding of how a customer will load their product ensures the best results are achieved.

September 7, 2022

The evolving test requirements for Electric Vehicle battery packs means test specifications are constantly being pushed to new boundaries. JTS has risen to these challenges with our range of containerised test chambers. With extensive experience in the design and build of reliable high-performance bespoke environmental test chambers we provide solutions to large multi-national companies, both here in the UK and overseas.

July 13, 2022

One of the exciting things about the work we do at JTS is the fact that no two projects are the same. Customer needs can be varied and sometimes the solution seems impossible, but most are issues that can be resolved, especially if JTS are invited into discussions at the early stages of a project. We have worked through an extensive list of site complication over the course of supplying chambers all over the UK – few are new to us.

April 14, 2022

JTS have recently worked with a great customer who needed help to resolve a dilemma. They were in the process of relocating to a fantastic new facility but their current chamber was just not up to being moved again and the existing cooling plant was extremely dated and inefficient. The project had lost valuable time in the pre-planning stage and delivery was getting critical, so the customer needed to find someone that would be able to design, build and install the chamber in a tight time frame.

Keeping you up to date...

By richard

•

October 17, 2025

We’re excited to welcome Alan Phillips to our service team. Alan joined us this summer and has already been making a big impact, helping customers get the very best out of their test chambers. 👏 At JTS, we know that regular servicing is the key to keeping your equipment reliable, accurate, and compliant. That’s why we offer a comprehensive Service Package designed to: ✅ Extend equipment lifespan ✅ Prevent costly breakdowns ✅ Maintain testing accuracy & compliance Our expert technicians provide: 🔧 Full functional checks 📏 Calibration & performance verification ⚙️ Replacement of worn parts 📝 Detailed service reports With JTS, you get fast, efficient service from specialists who know your chambers inside out — so you can keep operations running smoothly with minimal downtime. 📅 Ready to book your service? Drop us a message or get in touch today for your quotation andrea@jts-test-chambers.co.uk

By richard

•

September 19, 2025

James Technical Services Limited having been involved in electric car, battery development and testing over the past 7 years have now installed two 11kW charging points at the factory in Talgarth mid Wales. These points can be used by customers and employees 😊 JTS have always been following the progress of the battery development and have purchased their first electric vehicle which will be used by the employees to carry out sales / site visits. The container test chamber below is used by various car manufacturers for electric vehicle battery testing. This is just one example of a battery testing facility JTS can supply.

October 15, 2024

JTS were asked by local councillor William Powell to help out refreshing a storage container used by Talgarth Town FC juniors and ladies. After some initial discussions and a quick cad mock up to agree the paint scheme the JTS team began to work on the project. This happened with the help of the Black Mountains College (Power) and Talgarth Building Supplies (Paint) and the JTS workforce. As you can see the container has had a new lease of life and we hope the guys using the container like the paint work! ‘Good news TTFC under 10’s celebrated a home victory with the team having a photo and the container used as a back drop!’

July 22, 2024

James Technical Services Limited having been involved in electric car, battery development and testing over the past 7 years have now installed two 11kW charging points at the factory in Talgarth mid Wales. These points can be used by customers and employees 😊 JTS have always been following the progress of the battery development and have purchased their first electric vehicle which will be used by the employees to carry out sales / site visits. The container test chamber below is used by various car manufacturers for electric vehicle battery testing. This is just one example of a battery testing facility JTS can supply.

By Gillian

•

February 1, 2023

An issue faced by many customers is how to achieve the most test capacity without impacting on chamber performance. Putting the maximum test load in and still achieving even distribution and stability is a challenge when building bespoke equipment. Airflow is key and having a good understanding of how a customer will load their product ensures the best results are achieved.

September 7, 2022

The evolving test requirements for Electric Vehicle battery packs means test specifications are constantly being pushed to new boundaries. JTS has risen to these challenges with our range of containerised test chambers. With extensive experience in the design and build of reliable high-performance bespoke environmental test chambers we provide solutions to large multi-national companies, both here in the UK and overseas.

July 13, 2022

One of the exciting things about the work we do at JTS is the fact that no two projects are the same. Customer needs can be varied and sometimes the solution seems impossible, but most are issues that can be resolved, especially if JTS are invited into discussions at the early stages of a project. We have worked through an extensive list of site complication over the course of supplying chambers all over the UK – few are new to us.

April 14, 2022

JTS have recently worked with a great customer who needed help to resolve a dilemma. They were in the process of relocating to a fantastic new facility but their current chamber was just not up to being moved again and the existing cooling plant was extremely dated and inefficient. The project had lost valuable time in the pre-planning stage and delivery was getting critical, so the customer needed to find someone that would be able to design, build and install the chamber in a tight time frame.